The Indian demand for ultrapure salt of pharmaceutical applications, currently worth US$ 6.5 M, is projected to see a growth of 8.5% through to 2028 to reach 38,000 metric tons. As there is, no major manufacturer of pharmaceutical sodium chloride in India, and several small manufacturers may not meet the projected demand, it is necessary to establish a process for large volume production in continuous basis. Considering the growing demand, lowest market price (363 US$ /Ton) after China and 3rd largest salt producing country in the world, India can play a global role in this sector.

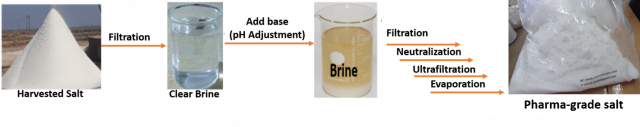

- It is a combination of chemical and physical method to separate the impurities to get the Pharma-grade salt.

- The process does not uses expensive BaCl2 which also toxic in nature.

- This process can be scaled-up as a continuous process without the time consuming recrystallization step.

- The process can be easily tuned as per the requirement.

- The production cost is very less to sustain in the market.

The process has several advantages over existing processes. Hence, this process has huge business scope considering the cost and easiness to scale-up.

The process is environmental friendly. The solid by-product Magnesium hydroxide along with other metal hydroxides can be used for derive other magnesia chemicals.

Raw NaCl, NaOH/CaO/Na2CO3

Brine tank with agitator, Nutsche filter, Single/Multi-stage evaporator, Ultrafiltration unit, Centrifuge, process pump, Dryer

Production cost of the salt will be around ₹13-14/kg.

Technical specification of each component, design drawing & layout, installation & commissioning, demonstration, basic training for the process (SOP).