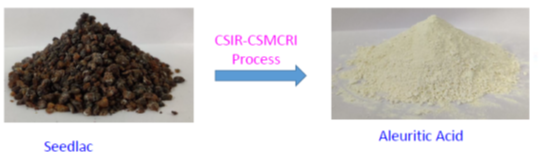

Aleuritic acid (9, 10, 16-trihydroxpalmitic acid) is an intermediate used mainly used in the perfumery industry, for the preparation of “musk” aroma compounds as well as medicinal and bioactive compounds. Aleuritic acid is a natural product obtained by the alkaline hydrolysis of seedlac and purification by various steps including recrystallization and charcoal treatment. The existing process for the recovery of aleuritic acid is very tedious and it needs 15-20 days per batch production. Also the recovery of aleuritic acid is 12-14% yield w.r.t. seedlac, results less profit for the manufacturers. Sometimes the quality of the product is not up to the standards of acceptable purity. Hence, better process of recovery of aleuritic acid are required to increase the yield and purity also to reduce the duration and cost of production process. The present technology addresses the recovery of aleuritic acid with improved yield and purity by reducing the time and also it is cost-effective process.

An improved process of recovery of aleuritic acid from seedlac by reducing the reaction time with improved yield and purity,

Reduces the environmental pollution meanwhile enhance the economics to the aleuritic acid manufacturers.

Aleuritic acid manufacturers, ready at lab scale demonstration.

Yes, it reduces the environmental pollution by recovering the value added products in the process.

Licensed to industry.

Customer is producing the aleuritic acid with the present technology.

Seedlac, alkali, sodium chloride

As desired by the customer for their production.

- An improved process for recovery of aleuritic acid from seedlac by reducing the reaction time with improved purity.

- As informed by the customer, the product is exported to foreign countries.

An improved process of recovery of aleuritic acid from seedlac (seedlac should be provided by the industry).