| Title of Process/ Know-how/ Product/Design/Equipment

Land-based cultivation of edible green seaweed Ulva from spore-based seedlings

IPR Status & Details:

IPR filed (Appl. No. 202411099850)

Application/Uses/Problem being addressed

Among macroalgae, Ulva stands out due to its versatility and health benefits (contains up to 26% protein on dw basis), making it valuable for the functional food market and global food needs. However, Ulva's seasonal nature and reproductive behavior pose challenges to its continuous cultivation, hindering sustained production. Establishing a cultivation technique through artificial seed production is crucial for ensuring a consistent supply of high-quality biomass and safeguarding wild seaweed resources. Traditional methods for seedling production have limitations, such as relying on sexually matured plants in the wild and vulnerability to contamination. The technology developed here gives year-round Ulva seedling production method followed by cultivation in tanks under semi-controlled laboratory conditions to address these challenges.

Salient Technical Features including Competing Features/ Impact

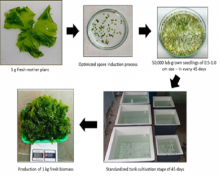

The technology involves standardization of method for consistent production of Ulva’s spore-based seedlings at a scale of 1,00,000 seedlings per batch of 45 days. It has demonstrated the use of various abiotic stresses like fragmentation, salinity, fresh-water treatment, desiccation, temperature and a combined stress to get maximum number of viable seedlings consistently from a minimum use of mother tissue. In addition, a 45-day semi-controlled laboratory tank cultivation protocol has also been established. Media, stocking density, seedling size, light illumination were standardized at each stage of tank-based cultivation with different customized tanks, with specific conditions and nutrient compositions, which promote maximum growth. The invention provides a systematic approach to tank-based Ulva cultivation using spore-based seedlings, offering benefits such as increased biomass production, reduced mortality rates, and sustainability.

TRL Level & Scale of Development:- TRL 4 TRL Reference

Lab scale production @ 1,00,000 spore-based seedlings of size 0.5-1.0 cm in a batch of 45 days has been achieved.

Semi-controlled environment @ 2 kg of fresh biomass production from those spore-based seedlings has been achieved in land-based tanks in additional 45 days.

Business scope & opportunity (in terms of scale, cost, market etc.)

Green seaweed market is likely to reach USD 2.09 billion by 2028 growing with a rate of 6.9%. Ulva, a genus of green seaweed, holds immense promise for land-based aquaculture due to its cosmopolitan distribution and high biomass productivity (Jansen et al. 2022), offering rich nutritional content vital for industrial applications. As consumers become increasingly health-conscious and seek out natural and sustainable food options, the demand for Ulva and other seaweed-based products in the functional food market is expected to continue growing. In addition, valuable compounds present in Ulva can be exploited for use in food, cosmetic, energy, and pharmaceutical applications (Vaghela et al. 2023). Extract derived from Ulva also known to provide abiotic stress tolerance to crop plant (Latique et al. 2021), having application in agriculture sector also.

This method will give continuous supply of Ulva raw material throughout the year which necessary for the survival of any Ulva based industry.

Scale and cost will vary depending on requirement of seedling material.

Environmental Considerations

The method follows non-polluting practices, does not require any harmful chemicals. As it is land-based cultivation can be deployed to any coastal area of the country without harming natural ecosystem of the sea.

Status of Licensing:

Not yet licensed

Status of Commercialization:

Though ready for deployment

Major Raw Materials Needed

Ulva mother plant stock

Major Plant Equipment and Machinery Required

Requires temperature (25-28 °C) and light controlled seaweed culture laboratory kind of set up and tank-cultivation facility under control and semi-controlled condition, customized tanks (PE plastic bags reactor), shade and small farm to maintained adequate stock and acclimatized the newly transported Ulva seedling. Adequate seawater and media is also require.

Techno-Economics

Starting with 5 g fresh biomass, 1,00,000 seedlings of size 0.5-1.0 cm can be produces which can be further cultivated in tanks to give 2 kg fresh biomass in total 90 days.

This requires only one manpower. Current prize of 1 kg dry biomass in India is around Rs. 250-300 per kg. 1 kg fresh biomass contains 85% moisture.

Technology Package

Know-how for spore-based seedling generation and subsequent demonstration of tank cultivation for one cycle;; License fee and other financial details would be provided on request.

| Technology Photographs